Project overview

Project Overview

Scope of our work:

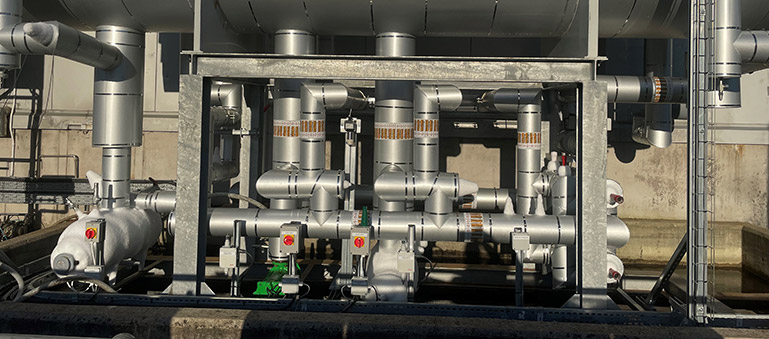

Noble Foods, a leading UK-based producer of high-quality eggs and egg-based products, wanted to expand its production capacity and needed to install an ammonia refrigeration system into a newly acquired factory.

Tasked with redesigning critical components and updating the system for optimal performance under new operating conditions, we identified that the existing ammonia vessels configuration and design parameters wouldn’t meet the new required operating conditions or temperatures.

As the existing compressors were to be re-used the compressor selection was fixed, we collaborated with the appointed spiral manufacturer and reverse-engineered the evaporators against the compressors to ensure the capacity was achieved.

The existing high-temperature compressor was also carefully assessed for its low-temperature capability – including oil cooling, motor size and speeds, and Vi requirements – to ensure effective operation.

Our expertise in system analysis, component compatibility and compliance meant we were able to reconfigure the system to effectively meet the client’s needs. By coordinating with other suppliers and reverse-engineering key components, we delivered a compliant, robust refrigeration solution to handle the production requirements.

This project highlights our ability to retrofit and optimise existing systems, collaborating with manufacturers to deliver solutions that align with both current regulatory standards and our client’s evolving needs.

Patrick Wood, Consumer Foods Operations Director at Noble Foods, said: "We’re delighted to partner with Cambridge HOK Refrigeration as our trusted supplier for all refrigeration services and installations. Their expertise plays a key role in supporting our operations and ensuring efficiency and quality at every step."